The manufacturing facilities of ProLact are compliant not only to the highest regulatory standards, but also comply with our own high requirements and specifications. The manufacturing facilities are fully compliant with all statutory and industry regulations in the industry, such as GMP (Good Manufacturing Practice), HACCP (Hazard Analysis and Critical Control Points), ISO 22000:2015 (Food Safety Management System), FSSC 22000 (Management of food safety risks throughout the supply chain), Halal and FDA requirements. In addition the manufacturing facilities are certified for ISO 9001 (Quality Management), ISO 14001 (Enviromental Management), ISO 26000 (Social responsibility), Vegan, etc. All of the certifications are being audited each year to make sure compliance is always at the highest standards.

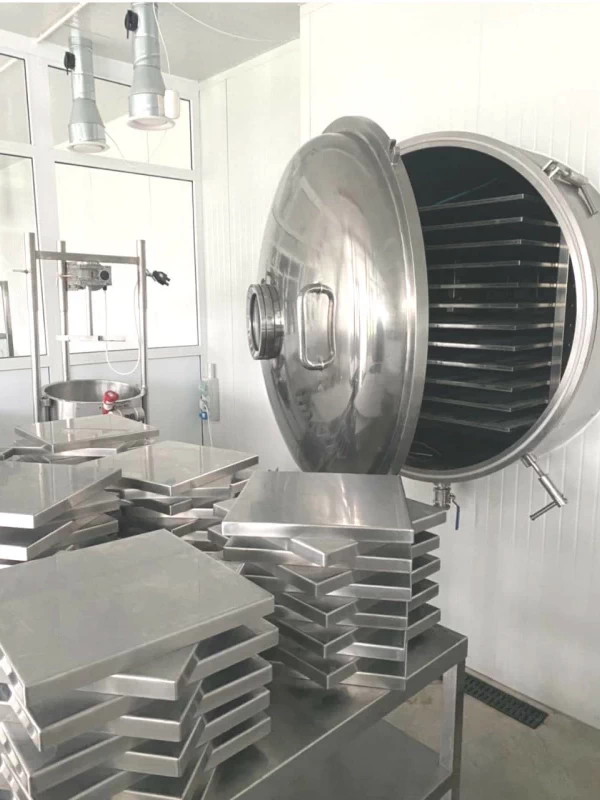

Manufacturing facilities are equiped with the most up to date professional industry equipment, such as bioreactors, freeze dryers and packaging machines for various types of packaging, based on the requirements of our clients. Such packaging solutions include: probiotics in capsules (Vegan/HPMC or gelatine), probiotics powder (in containers, zip pouches or sticks), capsules in containers, capsules in blisters, probiotics in sachets, etc.

The probiotics manufacturing plant has strict environmental control, including temperature, humidity and atmospheric pressure. Last, but not least important is the surrounding green environment, that allows for healthy recreation and relaxation of our staff.

Being one of the leading contract manufacturing facilities for probiotics in Europe, ProLact offers not just unprecedented quality, hygene and strict adherence to all industry standards, but also know-how in product development. Our facility is equipment with a small development center for new probiotic formulas. For larger and more complex projects we rely on our scientific team at the University of Food Technologies in Plovdiv - one of the largest specialised higher education institutions in Europe.

Copyright © ProLact Ltd. All Rights Reserved!